I. Introduction: Why MBR Design Matters

Hook: In an era of tightening effluent standards and shrinking plant footprints, Membrane Bioreactor (MBR) systems deliver Class 1A+ permeate quality in 30–50 % less space than conventional activated sludge. Yet 70 % of MBR failures stem from oversized membranes or under-aerated tanks—avoidable with rigorous design calculations.

Target Audience: Wastewater engineers, EPC consultants, plant managers, and OEMs specifying MBR for municipal or industrial projects.

Goal: Deliver a step-by-step, formula-driven methodology that turns raw influent data into a bankable MBR layout—complete with redundancy, fouling control, and CAPEX/OPEX guardrails.

II. MBR Fundamentals: Key Parameters & Concepts

| Parameter | Symbol | Unit | Typical Range | Design Impact |

|---|---|---|---|---|

| Design Flow | $Q$ | $\text{m}^3/\text{day}$ | — | Scales everything |

| Peak Factor | $PF$ | — | 1.5–2.5 | Handles diurnal spikes |

| Design Flux (Net) | $J_{\text{design}}$ | LMH | 15–22 (municipal) 8–18 (industrial) | Lower $J$ = lower fouling |

| HRT | $HRT$ | hr | 4–8 | Shorter than CAS |

| SRT | $SRT$ | day | 15–30 | Enables full nitrification |

| MLSS | $MLSS$ | mg/L | 8,000–12,000 | 3–4× CAS concentration |

| F/M Ratio | $F/M$ | kg BOD/kg MLVSS·d | 0.05–0.15 | Low food = low yield |

Membrane Geometry Quick-Compare

| Hollow Fiber (HF) | Flat Sheet (FS) |

|---|---|

| Higher packing density | Easier cleaning |

| Sensitive to hair/debris | Robust against rags |

| $J_{\text{peak}}$ up to 35 LMH | $J_{\text{peak}}$ up to 30 LMH |

HNS Water Tech FS modules (40 m²/unit) are used in the examples below.

III. Core Calculation Steps (The Practical 5-Step Workflow)

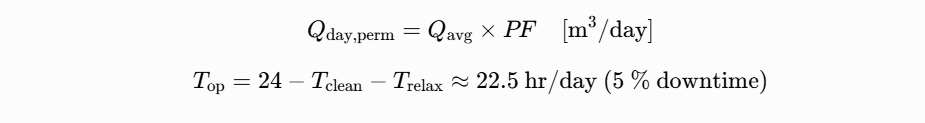

Step 1 – Daily Permeate Volume & Operating Window

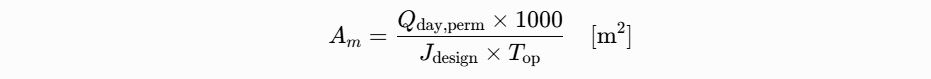

Step 2 – Total Membrane Area

- Municipal secondary: 18–22 LMH

- Food & beverage: 12–16 LMH

- Petrochemical: 8–12 LMH

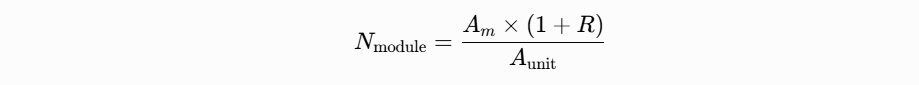

Step 3 – Module Count & Redundancy

$R$ = 10–20 % redundancy (one train offline for CIP).

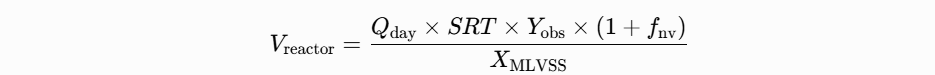

Step 4 – Biological Reactor Volume

Typical inputs: $Y_{\text{obs}}$ = 0.12 kg VSS/kg BOD, $f_{\text{nv}}$ = 0.4, $X_{\text{MLVSS}}$ = 0.75 × MLSS.

Cross-check HRT:

Step 5 – Scouring Air Demand

$SAD_m$ = 7–10 Nm³/hr/m² (FS) or 6–8 Nm³/hr/m² (HF) at 8–10 kPa.

IV. Case Study: 500 m³/day Municipal MBR (Real HNS Project)

| Input | Value |

|---|---|

| $Q_{\text{avg}}$ | 500 m³/day |

| $PF$ | 2.0 |

| $J_{\text{design}}$ | 20 LMH |

| $T_{\text{op}}$ | 22.5 hr/day |

| $A_{\text{unit}}$ | 40 m² (HNS FS) |

| $R$ | 15 % |

| $SRT$ | 20 days |

| $MLSS$ | 10,000 mg/L |

| $SAD_m$ | 8 Nm³/hr/m² |

| Output | Result |

|---|---|

| $Q_{\text{day,perm}}$ | 1,000 m³/day |

| $A_m$ | 2,222 m² |

| $N_{\text{module}}$ | 64 units (4 trains × 16) |

| $V_{\text{reactor}}$ | 208 m³ |

| $HRT$ | 6.0 hr |

| Scouring air | 17,776 Nm³/hr ≈ 300 L/s |

Layout: 4 parallel membrane tanks, each with 16 FS cassettes; CIP every 6 months.

V. Conclusion & Call to Action

MBR success = flux discipline + SRT control + aeration precision. Oversizing membranes by 30 % inflates CAPEX by €150k–€300k per 1,000 m³/day; undersizing invites weekly CIP.

Ready to size your next MBR with zero guesswork? HNS Water Tech provides free Excel design calculators, CFD-validated scouring maps, and turnkey FS modules.

📞 [Click to Book a 30-min MBR Design Review & Quote] or email [email protected] with your influent BOD/COD/NH₃ data.