Mastering MBR Systems: Process Flow and Design Calculations Explained

The MBR (Membrane Bioreactor) is a revolutionary wastewater treatment technology that combines conventional activated sludge biological treatment with a high-tech membrane filtration system. By integrating these two processes, MBR systems offer superior effluent quality in a much smaller footprint compared to traditional methods. 💧

Whether you’re an engineer, a plant operator, or simply curious about modern water treatment, understanding the MBR process flow and its design principles is essential. This guide breaks down everything you need to know.

The MBR Process Flow: A Step-by-Step Breakdown

The magic of an MBR system lies in its simple yet highly effective process. Wastewater goes through several key stages to emerge as high-quality reusable water.

Step 1: Pretreatment – The First Line of Defense

Before wastewater can enter the bioreactor, it must be pre-treated. This crucial first step involves passing the influent through fine screens (typically 1-3 mm) to remove large solids, hair, fibers, and grit.

Why is this so important? Pretreatment protects the delicate membrane surfaces downstream from physical damage and prevents clogging, ensuring the system runs smoothly and reducing maintenance costs.

Step 2: Biological Reaction – The Heart of the System

Next, the screened wastewater enters the bioreactor tank. This is where the biological heavy lifting occurs. The tank contains a high concentration of microorganisms known as activated sludge. These microbes are the workhorses of the system, consuming organic pollutants and converting nutrients like nitrogen and phosphorus.

To keep the microorganisms healthy and efficient, a high concentration of them is maintained, measured as Mixed Liquor Suspended Solids (MLSS). Air is continuously pumped into the tank to provide the dissolved oxygen (DO) necessary for this aerobic process. 🔬

Step 3: Membrane Separation – The Key to Superior Quality

This is what sets the MBR apart. Instead of using a traditional large clarifier or settling tank, the mixed liquor from the bioreactor is passed through advanced membrane modules. These modules contain thousands of hollow fibers or flat sheets with microscopic pores (typically 0.04 to 0.4 microns).

The membranes act as a physical barrier, allowing crystal clear water (called permeate) to pass through while completely retaining all microorganisms, suspended solids, and pathogens. The result is an exceptionally high-quality effluent that is often clear enough for direct reuse.

Step 4: Effluent & Sludge Management

The treated water, or permeate, is drawn through the membranes using a light suction pump and is ready for disinfection or discharge.

Meanwhile, the sludge that is left behind becomes more concentrated. A portion of this concentrated sludge is continuously returned to the bioreactor to maintain the optimal MLSS concentration. Any excess sludge produced is periodically wasted (removed) from the system for further treatment.

Step 5: Membrane Cleaning & Maintenance

To ensure consistent performance, membranes need to be cleaned regularly. This is typically an automated process that includes:

- Physical Cleaning: Regular backwashing with permeate to dislodge accumulated solids.

- Chemical Cleaning: Periodic “maintenance cleans” with chemicals like chlorine and citric acid to remove organic and inorganic foulants.

MBR Design Calculations: From Theory to Practice ⚙️

Properly sizing an MBR system is critical for its performance and cost-effectiveness. The central calculation revolves around determining the total required membrane area.

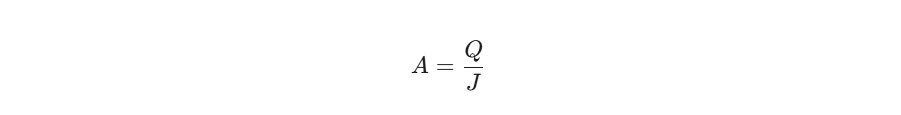

Core Design Formula: Calculating Membrane Area

The fundamental formula for MBR design is:

Where:

- A = Total Membrane Area required (in m²)

- Q = Plant Design Flow Rate (e.g., in m³/day or L/h)

- J = Membrane Flux (in L/m²·h, often abbreviated as LMH)

Membrane Flux (J) is the most critical parameter. It represents the volume of water that passes through a square meter of membrane surface area per hour. Flux is influenced by water temperature, influent quality, and the desired level of system robustness. A conservative flux is chosen to prevent rapid fouling.

Practical Calculation Example:

Let’s design a system for a small community.

Given:

- Daily Wastewater Flow (Q): 1000 m³/day

- Design Membrane Flux (J): 20 L/m²·h (LMH)

- Area per Membrane Module (A_unit): 50 m²

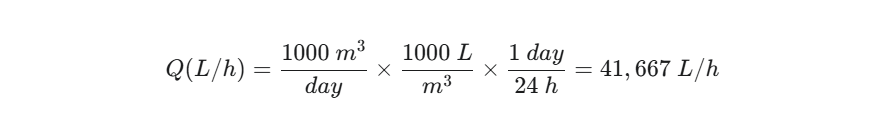

Step 1: Convert Daily Flow to an Hourly Rate

First, we need our flow rate and flux to be in compatible units (hours).

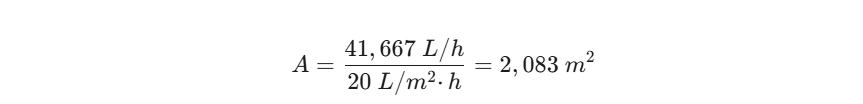

Step 2: Calculate the Total Required Membrane Area (A)

Now, we use the core formula.

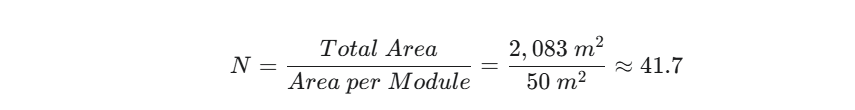

Step 3: Calculate the Number of Membrane Modules (N)

Finally, we determine how many modules we need to achieve this total area.

Therefore, we would need 42 membrane modules for this system.

Other Critical Design Factors

- Aeration Requirements: In an MBR, air is needed for both the biological process and for membrane scouring (air bubbles scrub the membrane surface to reduce fouling). This is calculated using the Specific Air Demand per m² of membrane (SADm).

- MLSS Concentration: Designers must choose an optimal MLSS range (typically 8,000-12,000 mg/L). Higher MLSS allows for more treatment in a smaller tank but requires more energy for aeration.

Conclusion: A Superior Solution for Modern Wastewater Treatment

The MBR process provides a robust, compact, and highly efficient solution for water treatment. By combining biological degradation with physical membrane separation, it consistently produces high-quality effluent that meets stringent discharge regulations and is suitable for water reuse. With careful design and proper operation, an MBR system is a powerful tool for achieving a cleaner, more sustainable water future.