Overcome Your Toughest Wastewater Challenges with Our Advanced MBBR Media

EnquiryContact us to get !

- Free design suggestions

- Product Technical details

- Full product catalog

Facing stricter effluent regulations? Running out of space for expansion? Struggling with high operational costs and maintenance headaches?

Your wastewater treatment challenges require a modern, powerful solution. Stop pushing outdated systems to their limits. It’s time to unlock new levels of efficiency, capacity, and reliability with HNS Watertech’s advanced MBBR (Moving Bed Biofilm Reactor) Media.

Transform Your Treatment Plant

Our MBBR media is more than just a component; it’s a complete system upgrade. By creating a massive, thriving ecosystem for pollutant-removing bacteria, it empowers you to:

- ✅ Dramatically Increase Treatment Capacity Retrofit your existing tanks to handle significantly higher loads without costly and time-consuming civil works. De-bottleneck your entire process and create room for future growth, all within your current footprint.

- ✅ Consistently Meet the Strictest Effluent Limits The highly resilient, specialized biofilm achieves superior removal of BOD, COD, and ammonia. Confidently meet even the most stringent nutrient discharge regulations, day in and day out.

- ✅ Slash Operational Costs and Maintenance Our self-cleaning carriers operate continuously without clogging, eliminating the need for complex maintenance routines. The efficiency of the process can also lead to significant energy savings from reduced aeration demands.

- ✅ Build a System That Lasts for Decades Engineered from 100% virgin HDPE, our media is built to withstand physical abrasion and chemical exposure. It’s a one-time investment for 20+ years of worry-free, high-performance operation.

How It Works: The Power of Biofilm in 3 Steps

We make advanced biology simple to implement.

- FILL: Our media carriers are introduced directly into your new or existing reactor tank, where they circulate freely.

- CULTIVATE: A dense, specialized biofilm naturally colonizes the immense, protected surface area of each carrier.

- TREAT: As wastewater flows through the reactor, this powerful biofilm supercharges the biological process, rapidly and efficiently breaking down pollutants.

The Proven Solution For Demanding Industries

From municipal towns to industrial factories, our MBBR media is a trusted solution for:

- Municipal Plant Upgrades

- Food & Beverage Production

- Pulp & Paper Mills

- Chemical & Petrochemical Processing

- Aquaculture & Fish Farming (RAS)

- And many more…

Placeholder for a customer testimonial:

“By retrofitting our main aeration basin with [Your Company Name]’s MBBR media, we increased our treatment capacity by 40% and finally met our ammonia limit, all without building a single new tank. It was a game-changer.” – Plant Manager, F&B Processing Facility

Let’s Engineer Your Success

Your project is unique. Your challenges are specific. You deserve more than a one-size-fits-all product.

Our team of process experts is ready to partner with you. We’ll help you select the perfect media, perform process calculations, and design the most effective and economical solution for your needs.

Schedule your free, no-obligation project consultation today.

[Request a Free Consultation] or email our engineering team at [email protected]

At HNS Watertech, we are committed to providing innovative and sustainable solutions for wastewater treatment. Our cutting-edge MBBR Media is designed to optimize the performance of Moving Bed Biofilm Reactor (MBBR) systems, ensuring efficient pollutant removal, reduced operational costs, and compliance with stringe😊nt environmental regulations. Whether you’re managing municipal wastewater plants or industrial effluent treatment, our MBBR media is the ideal choice for enhancing biological treatment processes.

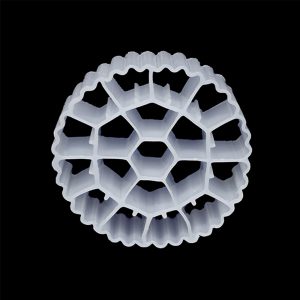

What is MBBR media?

MBBR media, also known as biofilm carriers, are specially engineered plastic elements that provide a large surface area for the growth of biofilms in wastewater treatment systems. These carriers are suspended in the reactor, allowing microorganisms to attach and thrive while breaking down organic matter, nitrogen, and other pollutants. The unique design of our MBBR Media ensures optimal mixing, oxygen transfer, and biomass retention, making it a cornerstone of modern wastewater treatment technology.

Why Choose Our MBBR Media?

Our MBBR Media stands out in the market due to its innovative design, durability, and proven performance. Here are the key reasons why wastewater treatment professionals trust our product:

- High Surface Area for Maximum Biofilm Growth

Our MBBR Media is engineered with a high specific surface area (up to 800 m²/m³), providing ample space for microbial growth. This results in higher treatment efficiency and the ability to handle larger pollutant loads in a compact footprint. - Durable and Long-Lasting Material

Made from premium-grade, UV-resistant polyethylene, our MBBR Media is built to withstand harsh wastewater conditions. With a lifespan of over 15 years, it offers a cost-effective solution with minimal replacement needs. - Optimized Design for Enhanced Performance

The unique geometry of our media ensures excellent mixing and prevents clogging, even in high-load conditions. This design promotes uniform biofilm distribution and efficient oxygen transfer, leading to consistent treatment results. - Versatile Applications

Our MBBR Media is suitable for a wide range of applications, including:

Municipal wastewater treatment

Industrial effluent treatment (food & beverage, textile, pharmaceutical, etc.)

Aquaculture water treatment

Upgrading existing treatment plants - Eco-Friendly and Sustainable

By enhancing the biological treatment process, our MBBR Media helps reduce energy consumption and chemical usage, contributing to a greener and more sustainable wastewater treatment process.

Benefits of Using Our MBBR Media

Compact System Design: Achieve high treatment capacity in smaller reactor volumes, saving space and construction costs.

Improved Treatment Efficiency: Effectively remove BOD, COD, ammonia, and nitrogen with minimal effort.

Easy Installation and Maintenance: Lightweight and easy to handle, our media requires no special tools for installation or replacement.

Cost-Effective Solution: Reduce operational and maintenance costs with a long-lasting, high-performance product.

Scalable and Flexible: Easily adapt to varying wastewater loads by adding or removing media as needed.

How Does MBBR Media Work?

The MBBR process combines the advantages of activated sludge and fixed-film systems. Here’s how our MBBR Media plays a crucial role:

Biofilm Formation: Microorganisms attach to the surface of the media, forming a dense biofilm that degrades organic pollutants.

Continuous Movement: The media is kept in constant motion by aeration or mechanical mixing, ensuring optimal contact between the biofilm and wastewater.

Pollutant Removal: The biofilm consumes organic matter, ammonia, and other contaminants, purifying the water.

Sludge Management: Excess biofilm naturally sloughs off the media, maintaining a balanced biomass without clogging the system.

This process results in a highly efficient, low-maintenance wastewater treatment solution that meets the needs of modern facilities.

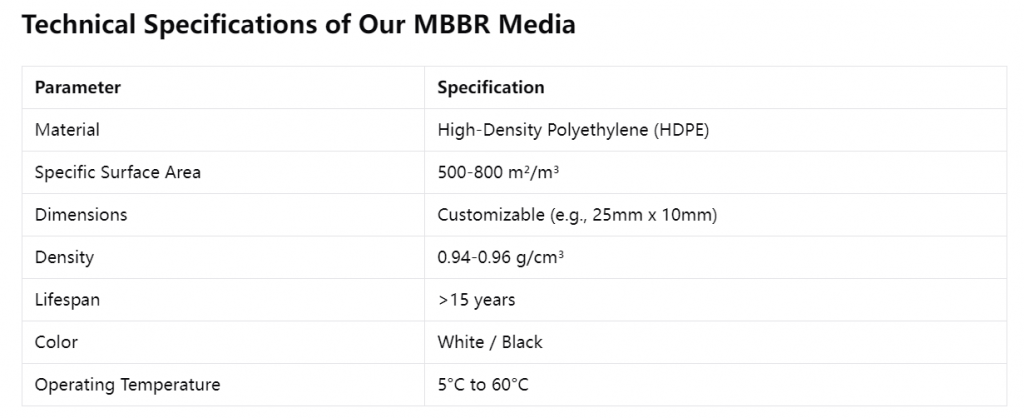

Technical Specifications of Our MBBR Media