Mbbr Media

EnquiryContact us to get !

- Free design suggestions

- Product Technical details

- Full product catalog

MBBR Filter Media

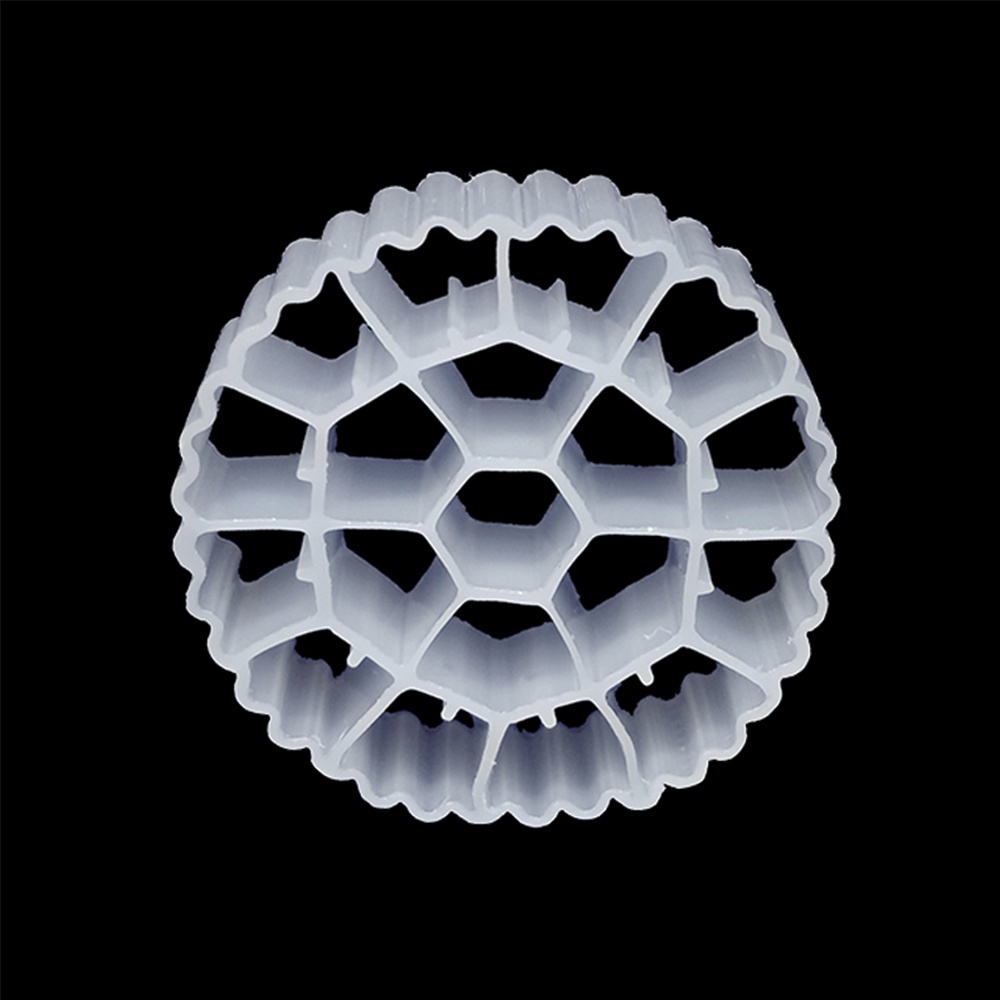

Based on the working principle of the Moving Bed Biofilm Reactor (MBBR), it combines the advantages of both attached-growth and suspended – growth systems. MBBR media manufacturers offer an advanced and high-quality wastewater treatment technology with high efficiency as expected. When you choose MBBR media, you’ll find that the investment cost is low, and the costs during operation, maintenance, and even replacement (if necessary) are minimal. The entire MBBR media setup provides a highly reliable and robust operation process.

The outstanding performance of this MBBR media will make other products in the same industrial category search for ways to catch up and reach the same high – end quality. Our proficient process uses high – grade raw materials to produce this MBBR media, which has already been applied in various industries. The end – product is remarkably competent and available for esteemed clients like you. Given the comprehensive demands of clients worldwide, we strive to do our best to solve the previously unresolved problems in wastewater treatment systems. Through high – end innovations with proven high – quality polymeric materials, we have achieved an improved quality standard for this media.

MBBR Filter Media Specification

As shown in the MBBR design manual, MBBR bio-media is a material that can be significantly applied to a wide range of wastewater flows, from 1,000 to 150,000 cubic meters per day. There are types of MBBR media with a density of 0.96 g/cm³ and a bulk density of 100 kg/m³. The dimensions can be 25 x 10mm or close to it, and they are available in various colors other than white. The sizes of this media offer a wide range of choices to meet consumers’ needs. The manufacturing process is carried out accordingly. Its sturdiness, abrasion resistance, and compact design make this MBBR media an excellent choice. By definition, MBBR stands for moving bed biofilm reactor. It is a biofilm process, distinct from rotating biological contactors (RBC), trickling filters, or biological aerated filters (BAF). Generally, MBBR wastewater treatment requires less space compared to the activated sludge system due to the more concentrated biomass.

| Mbbr Media Specifications | |||||||||||

| Model | unit | PE01 | PE02 | PE03 | PE04 | PE05 | PE06 | PE07 | PE08 | PE09 | PE10 |

| Spec | mm | Φ12*9 | Φ11*7 | Φ10*7 | Φ16*10 | Φ25*12 | Φ25*12 | Φ35*18 | Φ5*10 | Φ15*15 | Φ25*4 |

| Hole Numbers | pcs | 4 | 4 | 5 | 6 | 19 | 19 | 64 | 7 | 40 | 64 |

| Efficient surface | m2/m3 | >800 | >900 | >1000 | >800 | >500 | >500 | >1200 | >3500 | >900 | >1200 |

| Density | g/cm3 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 1.02-10.5 | 0.96-0.98 | 1.02-10.5 | 0.96-0.98 | 0.96-0.98 |

| Packing Numbers | pcs/cm3 | >630000 | >830000 | >850000 | >260000 | >97000 | >97000 | >33000 | >2000000 | >230000 | >210000 |

| Porosity | % | >85 | >85 | >85 | >85 | >90 | >90 | >92 | >80 | >85 | >85 |

| Dosing ratio | % | 15-67 | 15-68 | 15-70 | 15-67 | 15-65 | 15-65 | 15-50 | 15-70 | 15-65 | 15-65 |

| Membrane-forming time | days | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 |

| Nitrfication efficiency | gNH4-N/m3.d | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 300-800 | 500-1400 | 500-1400 | 500-1400 |

| BOD5 oxidating efficiency | gBOD5/m3.d | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 1000-5000 | 2500-20000 | 2500-20000 | 2500-25000 |

| COD oxidating efficiency | gCOD/m3.d | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 1000-5000 | 2500-20000 | 2500-20000 | 2500-25000 |

| Applicable temperature | ℃ | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 |

| Life-span | year | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 |

MBBR Media Features

- It is favorable for nitrification and has a longer sludge retention time.

- It can respond to load fluctuations without any operator intervention.

- It produces less sludge.

- It can resist any toxic shock.

- It can still perform excellently without relying on a secondary clarifier.

MBBR Media Purpose

The process flow diagram of the Moving Bed Biofilm Reactor (MBBR) reveals its purpose of preventing bio – clogging and the build – up of head loss. This reactor offers an advantage by enabling the system to avoid sludge recycling through its activated sludge systems.

Both the MBBR filter media and carrier media assist the system and can be used to retrofit existing activated sludge tanks. This is done to increase the volume that the current system can handle. Through MBBR design calculations, the capacity of an existing treatment plant can be enhanced without the need to increase the footprint by constructing new tanks.

When you purchase MBBR media, you can anticipate the following benefits:

- Higher Sludge Retention Time (SRT): It has an effective and elevated SRT, which is highly beneficial for nitrification.

- Automatic Response to Load Fluctuations: It can continuously respond to load changes without the need for operator intervention.

- Reduced Sludge Production: The amount of sludge produced is lower.

- Smaller Space Requirement: It does not demand a large area.

- Toxic Shock Resistance: It is strong enough to withstand toxic shocks.

- Independent Performance: Its performance is completely independent of the secondary clarifier.

MBBR Media Application

Application When constructing a system using this MBBR plastic media, initially, the system can be set to a relatively low filling level, for example, 40%. Subsequently, by adding more carriers, the filling level can be increased to 70%. The surface area of the MBBR media should also be taken into account, as it significantly influences the system’s performance. Installing a sieve at the tank outlet can enhance the system’s performance. It is an essential measure to prevent the plastic carriers from escaping during the aeration process.

Shipment Packaging

The MBBR media is packed in plastic woven bags, with each bag having a volume of 0.1 CBM.

A 20-foot container can hold 30 cubic meters, a 40-foot container can accommodate 60 cubic meters, and a 40-foot high-cube container can carry 70 cubic meters.

Delivery

Typically, the MBBR media are delivered within 20 days. For large orders, the delivery time will be determined according to the contract.