K1 K3 K7 Moving Bed Biofilm Reactor Bio Filter Mbbr Media for Water Treatment

EnquiryContact us to get !

- Free design suggestions

- Product Technical details

- Full product catalog

In an era of increasing demands for water quality, efficient, compact, and reliable wastewater treatment technologies are more critical than ever. As a leading manufacturer of Moving Bed Biofilm Reactor (MBBR) media, we provide the advanced carrier technology that empowers you to achieve superior treatment results with a smaller footprint and lower operational costs. Our MBBR media is the ideal choice for upgrading existing plants or designing new, high-performance facilities.

What is MBBR Media?

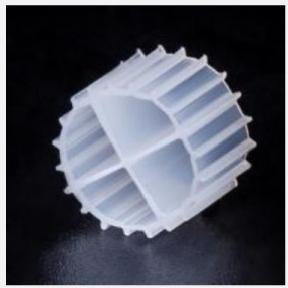

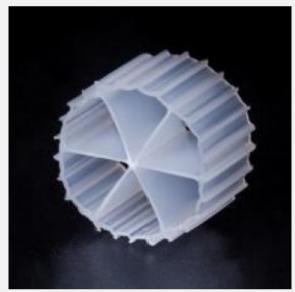

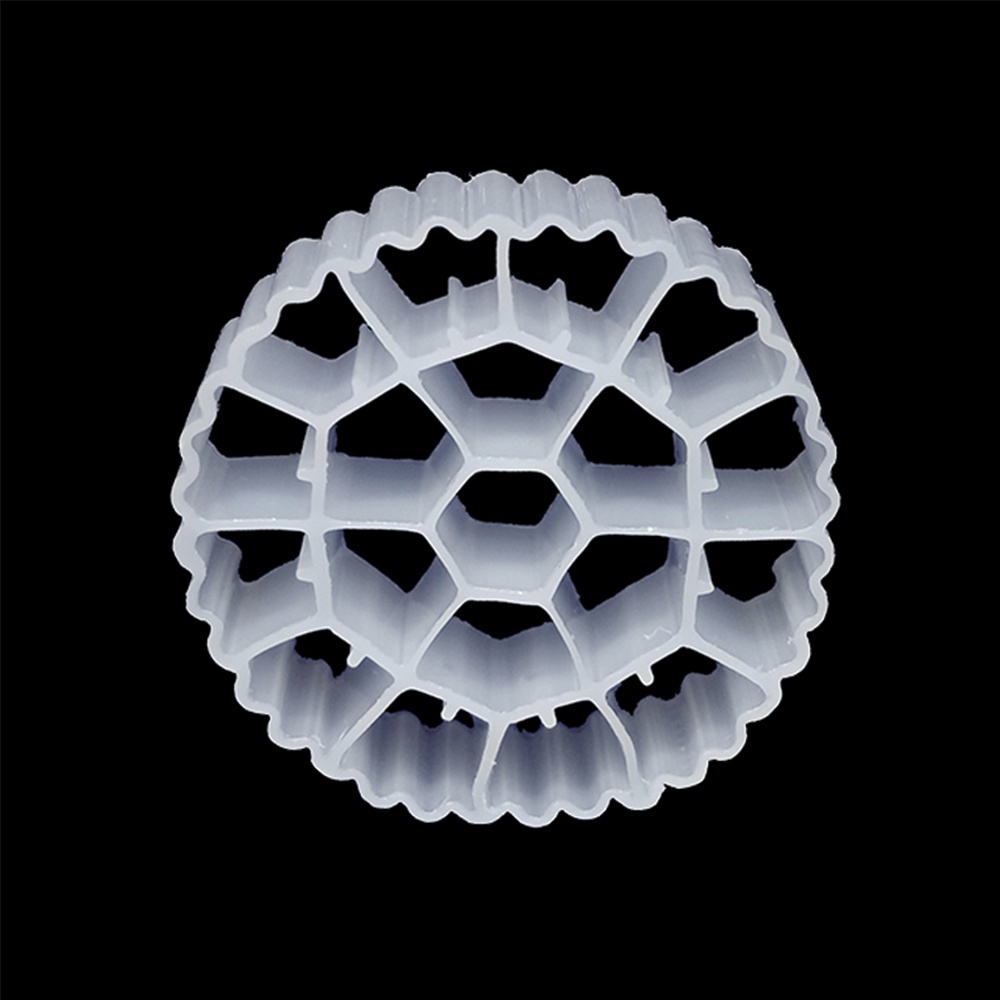

A Moving Bed Biofilm Reactor (MBBR) is a highly effective biological treatment process. The core of this technology is the MBBR Media—intelligently engineered plastic carriers designed to create a massive protected surface area for biofilm growth.

Think of them as “hotels for microbes.” These carriers are suspended and circulate within the reactor, providing a home for vast colonies of beneficial microorganisms. This robust biofilm efficiently breaks down pollutants in the wastewater, such as BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), and ammonia.

Key Features & Advantages

Choosing our MBBR media means choosing efficiency, durability, and peace of mind.

- ✅ Extreme Specific Surface Area for Maximum Efficiency Our media features a porous, multi-room geometric design, providing an immense effective surface area (up to >3500 m²/m³). This allows for a much higher concentration of microorganisms in a smaller reactor volume, dramatically increasing treatment efficiency and capacity.

- ✅ Premium Virgin HDPE for Unmatched Durability We use only 100% virgin High-Density Polyethylene (HDPE), never recycled materials. This guarantees superior mechanical strength, high impact resistance, and a service life of over 20 years, ensuring your investment is secure and long-lasting.

- ✅ Rapid Biofilm Formation for Stable Performance The hydrophilic surface and unique internal structure of our media promote rapid colonization by microorganisms (biofilm formation). Once established, the biofilm is protected from hydraulic shock, ensuring stable, consistent performance even under fluctuating load conditions.

- ✅ Smart Self-Cleaning Design for Zero Maintenance The constant, gentle movement of the media within the reactor, driven by aeration or mixing, allows for a natural self-cleaning action. This prevents clogging and channeling, eliminating the need for complex and costly backwashing systems and reducing operational maintenance to a minimum.

Our Product Series

We offer a diverse portfolio of MBBR media models to meet your specific water characteristics, flow rates, and process requirements. Whether you need maximum surface area for a compact space or a robust carrier for a high-load application, we have the solution.

| Item No. | Dimensions (mm) | Specific Surface Area (m²/m³) | Key Feature |

|---|---|---|---|

| MBBR08 | 10 x 5 | >3500 | Maximum Efficiency Model: The highest surface area on the market for projects with extreme space and performance demands. |

| MBBR92 | 30 x 5 | >1700 | High-Load Model: Combines very high surface area with a robust structure, perfect for tough industrial wastewater. |

| MBBR78 | 25 x 4 | >1600 | High-Performance All-Rounder: A perfect balance of size and efficiency for a wide variety of applications. |

| MBBR05 | 11 x 7 | >1000 | Classic K1-Type Upgrade: The industry-standard size but with a higher surface area, ideal for municipal WWTP upgrades. |

| … | … | … | Contact us for our complete technical data sheet and full product catalog. |

Wide Range of Applications

Our MBBR media has been successfully implemented in water treatment projects across the globe:

- Municipal Wastewater Treatment Plants (WWTPs): For new plants or upgrading existing activated sludge processes to increase capacity and improve effluent quality.

- Industrial Wastewater Treatment: Especially effective for high-strength organic wastewater from industries like food & beverage, pulp & paper, petrochemical, and textiles.

- Recirculating Aquaculture Systems (RAS): Provides highly efficient nitrification (ammonia and nitrite removal) to maintain water quality for healthy fish farming.

- Denitrification & Tertiary Treatment: Used in anoxic zones for total nitrogen (TN) removal and final effluent polishing.

Why Choose Us as Your Supplier?

- Direct Manufacturer: As the source factory, we offer the most competitive pricing and a stable, reliable supply chain.

- Strict Quality Control: Every batch, from raw material to finished product, undergoes rigorous testing to ensure consistent, high-quality performance.

- Expert Technical Support: Our experienced team can provide project consultation, process calculations, and installation guidance.

- Global Supply Capability: We have extensive export experience and can deliver our products safely and on time to any port worldwide.

Get Your Customized Solution Today!

Ready to enhance the performance of your wastewater treatment system?

Contact us now for a free technical consultation, system design, and product quotation!

Call me or email us directly at: [email protected]

Shipment Packaging

The MBBR media is packed in plastic woven bags, with each bag having a volume of 0.1 CBM.

A 20-foot container can hold 30 cubic meters, a 40-foot container can accommodate 60 cubic meters, and a 40-foot high-cube container can carry 70 cubic meters.

Delivery

Typically, the MBBR media are delivered within 20 days. For large orders, the delivery time will be determined according to the contract.